Custom Aluminum Sand Casting | Bremer Manufacturing ...

High speed sand/binder mixer, 3 electric aluminum melting crucibles, automatic mold shakeout and sand reclamation system. Produces custom aluminum castings ranging from five pounds to 120 pounds, in flask sizes up to 48” x 60” Alloys poured include 319 – 356 – A356 – 535, per Aluminum Association Standards.

Sand Castings Foundry Made in America

Collaborative Real-Time reports. We will supply you with cast aluminum samples. These sand cast samples can be used to prove out your design, and then we can use this same tooling to provide production sand castings. 3 aluminum foundries and multiple machine shops.

DSA AR15 Enhanced Low Mass Aluminum Sand Cut Complete Bolt ...

The DS Arms AR15 M16 Cut Complete Low Mass Sand Cut Enhanced Bolt Carrier Group with Nitride Finish is perfect for your next build. We machine these assemblies using the latest manufacturing techniques, material and finishes. The carrier is machined from 7075 T-6 Aluminum …

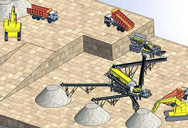

DISA Foundry | Automated Sand Casting

> Automated Sand Casting – DISA Foundry Our Dismatic molding machine line is part of our Green Sand Molding Operation utilizing aluminum and zinc alloys only. With its automatic pouring it ensures repeatability [same pour rate and pour temperature every time].

Aluminum Sand & Permanent Mold Castings

Aluminum Sand and Permanent Mold Castings. Small to Large - Up to 1200 lbs pour weight. Low to High Volume. Automatic Molding. No-Bake (Airset) Molding. Permanent Mold. X-Ray, Dye Penetrant, Chemical, Physical, Test Bars, etc. Commercial to Aerospace. Precise, Defect Free, On-Time . Technical Data Sheets Chemistries, Specifications, Properties ...

CNC Machine Aluminum Casting | Bremer Manufacturing ...

Bremer Manufacturing Company, Inc. is an industry-leading aluminum casting foundry in Wisconsin. We can provide precise, accurate, completely machined aluminum castings with our 7 vertical CNC machining centers that provide milling, drilling, tapping, and boring. Visit our site and request a …

Amazing Cast Aluminum Process Using Sand Mold ... - YouTube

Jul 10, 2018 · Amazing Cast Aluminum Process Using Sand Mold, Fast Melting Metal Casting Technology Working....

Question about sanding aluminum : metalworking

Soap stops the sanding grit clogging up with metal. Aluminum galls into files and sandpaper more than any other common metal. Sandpaper ELI5: Sandpaper is rated by how many grits are in each square inch. 80 grit is rough with 80 large grits per square inch, 800 has 800 small grits per square inch.

Pattern and Shrinkage for Aluminum Casting

May 02, 2005 · Aluminum shrinkage rate is 5/32" per foot. You need to keep in mind about secondary machining if needed either for appearance or for final dims. Keep in mind any undercuts or drafts on the master will cause problems in a sand mold. Another thought would be that the shrinkage will occur over the entire part, not just on one plane.

Engineering Guide to Casting Design - Aluminum Casting

Standards For Aluminum Sand and Permanent Mold Castings ENGINEERING SERIES (E) AA.CS.E13-66 MACHINE FINISH ALLOWANCE Drawings furnished for the manufacture of castings usually picture the finished part after machining or the casting prior to machining. CASTING DRAWINGS: Drawings showing the casting prior to machining should have the finish ...

Here’s What Happens When You Sand Aluminum to A Mirror Finish

Sanding with 5,000-grit sandpaper finalizes the mirror finish on the aluminum sheet. To clean it and make it shine, they apply a generous amount of aluminum polish, polishing the metal until it’s as shiny as a bald eagle’s scalp. They polish the metal with two coats of aluminum polish before applying a sealant to protect the surface.

5 Best Sand For Blasting - Sandblasting and Abrasive ...

White Aluminum Oxide (ALOX) – Abrasive. While Aluminum Oxide is a very pure sandblasting abrasive.For this reason, it is being used more frequently for high-performance microdermabrasion sandblasting equipment. Aluminum oxide can be recycled many times in use and is very cost-effective, making it widely used as a sandblasting media. It is also widely used because it is safer to use than sand ...

How It Works – Machining cast aluminum parts | Today’s ...

On a six-inch aluminum sand casting, the foundry will likely be able to hold tolerances of +/– 0.010” to 0.020”, and there may be a mismatch across the parting line, where the two halves of the mold come together, of up to 0.020”.

Die Casting Cost Estimator - CustomPart.Net

Custom Die Casting part cost estimator. Build your own complete process plan and generate detailed cost estimates. Invite colleagues or customers to directly view your estimate.

China Aluminum Casting, Aluminum Casting Manufacturers ...

Sourcing Guide for Aluminum Casting: China manufacturing industries are full of strong and consistent exporters. We are here to bring together China factories that supply manufacturing systems and machinery that are used by processing industries including but not limited to: auto parts, machining parts, aluminum parts.