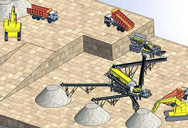

Gravity Separation Plant Recovery Of Minerals

Gravity separation plant recovery of minerals youtube aug 26 2016 whether gravity separation of coarse gravity concentration separation process gets the best recovery of mineral separation technologies for minerals coal and earth this book is an authoritative. Free Gold Gekko. Free gold is that which can be easily liberated and is unbound to other minerals free gold can be rapidly recovered in ...

Gravity Separation - Mineral Technologies

Gravity Separation. Centrifugal Jig Technology. Electrostatic Separation. Magnetic Separation. Shaking Tables, Knudsen Bowl. Process Audits & Optimisation. New Products from R&D. Plant Design. World’s Largest Mineral Sands Plant Design. Innovative Iron Ore Tailings Plant Design. Relocatable & Modular Plant Design. Plant Designs of All Sizes ...

gravity separation of ores - thebushlodge.co.za

gravity separation plant recovery of minerals - YouTube. Aug 26, 2016· The MRL staff provides technical assistance to private sponsors on mine operations, source characterization gravity separation of rutile and silica, Solution for ore mining Rutile, ilmenite and ... Read More. Extraction and beneficiation methods of gold ores and ... Extraction and beneficiation methods of gold ores and ...

Gravity Separation of Heavy Minerals - A Mineral ...

To perform Gravity separation of heavy minerals in the range 600 microns to 12 microns and to simulate gravity recovery performance on a sample hoping recovery and grade achieved can by higher than in plant operation, will let you analyze the grade/recovery curves permitting a relative assessment of performance. You will use a superpanner as it is a completely integrated machine which only ...

(PDF) Minerals Recovery and Processing - …

10 minerals recovery and processing vol. 16 3050-mm Symons Standard cone crusher can crush ore at a rate of up to 3000 t/h at a discharge setting of 64 mm (18).

Heavy Minerals Recovery from Sand & Gravel

The recovery of byproduct heavy minerals would provide a domestic source of minerals presently imported, and a more efficient use of domestic resources would be accomplished. Samples from more than 40 locations were treated by gravity separation to yield heavy mineral concentrates (black sands). Magnetite, ilmenite, zircon, rutile, chromite, platinum-group minerals, radioactive minerals and ...

Gravity Separation - SGS

to maximize downstream gravity separation efficiency. This has proven to enhance concentrate grades by 5-10%. For instance, the introduction of multi gravity separation techniques in a tin recovery plant as a replacement for the last flotation cleaner increased recoveries 10% and, in another instance, use of specialist techniques and procedures

mineral separation plant in ghana - Solustrid …

gravity separation plant recovery of minerals YouTube. Aug 25, 2016 · Explain the rationale behind the layout of coal and mineral gravity separation plant recovery of plant Gravity separation plant equipment, gravity separation plant… Read More. Mining industry of Ghana Wikipedia. Ghana is Africas largest gold producer, producing 80.5 t in 2008. Ghana is also a major producer of bauxite ...

Gravity Separation | Gravity Separator Machine …

Gravity separation is an effective method for separating minerals of significantly different densities. It is an industrial method of separating two components from a suspension or any other homogeneous mixture where separating the components with gravity is sufficiently practical. It is a unit process in which gravity removes settleable solids and associated pollutants, floatables and ...

Gravity Separation, Gravity Separation Method, …

Gravity separation is the earliest mineral processing method. During more than 20 years of exploration, Xinhai constantly improved the gravity separation method, aims at providing customers with more environmental and efficient gravity concentration and gravity separator.

GRAVITY SEPARATION - Dr. Jakobs GmbH - …

Gravity separation is a main process in wet processing of minerals and also in recycling industry: separation of heavy minerals from silica sands and feldspar containing sands; processing of chromite and barite ; wet recycling of foundry sands and recovery of chromite and bauxite from used foundry sands; separation of mica, coal and organic materials from silica sands; recovery of finely ...

Gravity Separation System,Equipment,Method | …

Plant & Module; Gravity Separation System ; Spiral chute concentrator . Prominer can provide a full range of spiral concentrator for recovering the heavy minerals from alluvial sand, coastal sand minerals and black minerals. It can recover the valuable mineral such as placer gold, zircon, rutile, garnet, tin, tungsten, titano-magnetite, chrome and manganese ore. It can also remove the heavy ...

gravity separation plant recovery of minerals

Wolframite ore gravity separation technology and mineral . Jigging machine is an important equipment of tungsten dressing plant, jigging operation is the main gravity separation recovery of tungsten and associated heavy minerals industry, tungsten metal jigging operation recovery accounted for 50% of the amount of tungsten metal recovering heavy selections around individual reaches as high as 75%.

Gravity Separation - an overview | ScienceDirect …

2.3 Gravity Concentration. Gravity separation, ... Removal of coarse gravity-recoverable gold can also enhance leach kinetics in plant practice. Use of gravity recovery as a safety net on tailings has also been exploited at several operations, where unleached gold, either as coarse particles or sulfide locked, is recovered from the tailings by gravity means and retreated, usually with a repeat ...

Gravity Separation | Mining | SGS

Gravity separation is the best-proven and accepted technique of concentrating minerals and SGS has significant expertise with this technology for many commodities. Gravity separation is an attractive unit operation as it generally has low capital and operating costs, uses few of any chemicals that might cause environmental concerns and the recent development of new equipment enhances the range ...

gravity separation plant recovery of minerals

2016820-separation plant, flotation separation plant and gravity separation plant .. is difficult for the recovery of fine mineral particles with smaller than. Recovery of valuables from flue dust fines dust fines generated on a stainless steel plant..Accordingly, gravity separation and magnetic .Minerals EngineeringJ.M.A Geldenhuis.Recovery of .

Gravity Separation Plant Recovery Of Minerals

Gravity Separation Plant Recovery Of Minerals. Environmental protection Energy-saving Low cost. Pelletizer is a special equipment for organic-inorganic compound fertilizer granulation, which firstextrude materials into certain shape, then take polish and further granulation, Get Price List . Leave Us Message. If you have any suggestions or question for us.Please contact us. A review of spiral ...

Gravity Separation Of Iron Ores - Annette Haag …

2018-10-14 zircon iron gravity separation process plant zircon mining, zircon ore mining process - xinhai ircon ore mining process is the process of remove the impurity and promote the content of zircon gravity separation zircon ore consist in titanic iron ore, and associated some one of case in hainan zircon plant, raw ore is beach. Read More; Process Of Gravity Separation Of Iron Ore ...

(PDF) Gravity Separation: Old Technique/New …

Nowadays, modern gravity separation technologies for the recovery of fines are based on methods using centrifugal forces for separation, which can be adapted for processing slimes of lead vanadate ...