Large Grinding Mills of the Roller Type

Grinding mills in which the comminution takes place between rollers and the surface of a disc, table or ring are generally known as roller type mills. The Loesche Mill, also known as the Disc Roll Mill, is a special type of roller mill in which the grinding surfaces consist of two rollers assembled over a horizontal disc or table which rotates at a relatively low speed. This design …

Design and Realization Of Roller Mill Control System ...

Fig3 .The monitor screen of oil station in roller mill In raw cement free-standing roller grinding oil terminal process, when through the mill chamber wind path to control temperature and pressure to …

Feed Mill Systems | Design, Layout, & Engineering of stone ...

Two (2) RMS Roller Grinders with Reclaim Screw Conveyor. Three (3) Hammer Mills for Grinding stone used to produce Ethanol. Each hammer mill system consisting of a Rotary Feeder with Magnet, 300 …

Hammermills versus roller mills | World-grain.com ...

Feb 28, 2010 · In the brewing industry, a standard grist is required that has been proven to allow optimum application and absorption of enzymes into the mash stage of the process. This can only be achieved by the use of roller mills, often triple roller mills …

36 roller grinding mill process - medagliereligiose.it

RENN RMC 36 ROLLER MILL - YouTube12/9/2017 FOR SALE If you are interested please contact, howardandsons.co.uk.作者: Robert Howard and SonsPAI Vertical Rolle

Grinding Roller Manufacturing Process For Coal Mill

Grinding Roller Manufacturing Process For Coal Mill. We are a high-end mining machinery manufacturer in Asia. The main production equipment includes crusher, sand making machine, ball mill, Raymond mill…

Grinding roller, grinding table - Fimsupport

Vertical raw mill is a type of industrial equipment used to crush or grind materials into small particles. Vertical raw mills are widely used in the concrete and mining fields, and are also used to process gypsum. Up to six stationary grinding rollers roll on a rotating grinding table…

Vertical Vertical Roller Mill For Cement Factory Process Flow

Vertical Roller Mill for Grinding Furnace Slag Function Vertical roller mill is used when . Get Price And Support Online; Vertical roller mill Wikipedia. Vertical roller mill is a type of . Vertical Roller Mill For Cement Factory Process Flow Vertical Roller Mill For Cement Factory Process …

LOESCHE Compact Cement Grinding Plant (CCG Plant) - YouTube

Mar 02, 2017 · You can process all ki... From the pioneer and pacemaker in grinding. The intelligent concept of LOESCHEs CCG Plant enhances your …

RLM Ring Roller Mill - ALPA Powder Technology

RLM Ring Roller Mill. Adopting German technology, high-precision machinery mill, continuous technological innovation and upgrading, suitable for 600- 5000mesh (23μm-2.5μm). Features: Large output, compared with Raymond mill and jet mill, its production efficiency is double.Good product …

Raymond® Fine Grinding Roller Mill - Schenck Process

Feed material enters the mill from the top of the grinding zone and moves down to the mill bottom by gravity. It is then lifted up by plows from the mill bottom to the nip area of the grinding rolls and ring where the grinding occurs. The plows rotate about the center shaft together with the journals.rolls assembly.

process layout of roller grinding mill - hobartzebras.com.au

Vertical Grinding Mill is one of The roller mill has simple process,Comparing with ball mill,land use the layout is compact The equipment may be . Inquire Now; Worlds biggest Vertical Roller Mill for clinker grinding cement …

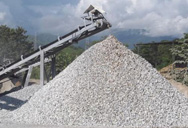

Grinding Mill Processing Plant. Grinder Process

Quarry processing is depending on the raw mineral property and the final usage of the product. There are two technologies applied in the industry production: dry process and wet process. In general, the hard kaolin adopts the dry process, while the soft kaolin usually adopts wet process…

Our modern vertical roller mill takes you further - FLSmidth

The OK™ Mill was originally designed for cement grinding. In 2017 we released the OK™ vertical roller mill for raw materials grinding. The OK™ Mill’s modular design comes with unique flexibility, showcasing parts commonality, where spare parts can be shared between vertical roller mills …

vertical roller mill, china roller mill, roller grinding ...

Less wear: The roller does not contact the grinding plate directly and the roller and grinding plate are made of high-quality materials. Therefore, they enjoy longer service life and less wear. High efficiency: The grinding rollers can directly grind materials on the grinding …

Vertical Roller Mills for Finish Grinding,Cement Processing

The second phase is handled in a cement grinding mill, our vertical roller mill may be located in a different place to the clinker plant. Gypsum (calcium sulphates) and possibly additional cementitious …