role raw mill ore mill ore plant - …

Ball Mill Gold Ore Portable In India. 2019-3-11gold ore concentration processhe crushing sections the gold ore from the mine site is always with size 0-400mm or 0-600mm after blastinge use the crushing plant to crush the raw gold ore into 0-8 or 0-10mmrimary grinding and classifying section the gold ore with the size 0-8mm or 0-10mm will be fed into the ball mill.

Cement mill - Wikipedia

A cement mill (or finish mill in North American usage) is the equipment used to grind the hard, nodular clinker from the cement kiln into the fine grey powder that is cement.Most cement is currently ground in ball mills and also vertical roller mills which are more effective than ball mills.

duties of raw mill attendant in cement plant | …

role of raw mill in cement plant. 10 Dec 2013 duties of raw mill attendant in cement plant. plants worldwide, because most cement role: It determines reliable and exact Coal mill. >> Get Price; about cement mill plant attendant – SAMAC.

PAI Vertical Roller Mill Training - YouTube

17-2-2016 · In this training module, well cover the operation of a vertical roller mill. This mill is commonly used in the cement industry in order to grind raw feed. Well describe the general arrangement ...

Stacker And Reclaimer | Stacker & Reclaimer | …

The stacker and reclaimer is the pre-homogenization system in the cement plant.As a necessary part of the cement production line, it can concurrently or respectively complete the stacking and reclaiming. The stacker and reclaimer plays a vital role in the limestone pre-homogenization, stabilize the condition of cement kiln, ensure the clinker quality.

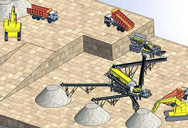

CEMENT PRODUCTION AND QUALITY CONTROL A. Cement ...

CONTROL A. Cement manufacturing Process Source:civilengineeringforum.me The whole process of cement manufacturing in Messebo Cement plant which consists of two separate Cement Production lines can be summarized into the following processes ;as can be seen in the process and Quality flow diagram below; 1. Quarrying and Crushing 2. Raw material ...

Cement Crusher | Cement Crusher For Sale | Jaw …

Cement crusher refers to the stone crusher in the cement industry, as a part of the cement plant, it plays a vital role in the cement production line.Before sending it into the raw mill, the cement raw material should be crushed into small sizes by the cement crusher.

responsibilities of supervisor in raw mill engineer in ...

duties and responsibilities of cement raw mill opera; raw mill flow chart in cement plant only; raw mill building in cement industry; good quality raw mill in cement plant; Summary of cement mill raw material vertical grinding work; raw mill hopper cement plant africa; mill limestone mill for cement raw material additives; small intermittent ...

Cement grinding Vertical roller mills versus ball mills

cement industry the ball mill was really an epoch-making breakthrough as for almost 80 years it was the predominant mill for grinding of raw materials and coal, and still today is the most used mill for cement grinding. Over the last three decades the vertical roller mill has …

Cement Production | Cement | Howden

Once the raw materials have been crushed into raw meal, they are transported to the kiln and Howden fans play an important role in super heating the meal into the cement clinker and then to cool the clinker. The clinker then has gypsum added and is moved into the cement mill to be ground into the final product.

The cement kiln - Understanding Cement

However, new cement kilns are of the dry process type. Dry process kilns. In a modern works, the blended raw material enters the kiln via the pre-heater tower. Here, hot gases from the kiln, and probably the cooled clinker at the far end of the kiln, are used to heat the raw meal. As a result, the raw meal is already hot before it enters the ...

Cement manufacturing - components of a cement …

Cement manufacturing: components of a cement plant. This page and the linked pages below summarize the cement manufacturing process from the perspective of the individual components of a cement plant - the kiln, the cement mill etc.. For information on materials, including reactions in the kiln, see the Clinker pages.

Cement plant information for Australian Steel Mill ...

Cement Plant information for Port Kembla can be found below. For full access to the database, purchase The Global Cement Report™, 13th Edition.

Cement Production: Raw Meal Production in Steps

Cement Production: Raw Meal Production in Steps Perfectly mixed, accurately fed without pulsation, and precisely weighed. The key word is quality! And this quality is achieved during cement production with exactly matched process steps. In the first stage, the raw meal is produced, as described below.

Raw Mix Preparation - ABB Group

Raw Mix Preparation Raw Mix Optimization Raw Mill Optimization ... material proportions in the raw mill feed. As in the former module, Model Based Control techno- ... cement plant. It puts the most modern software and control technology at the service of our customers.

Ball Mill for Sale | Mining and Cement Milling …

We provide ball mill equipment for cement plant, power plant, mining industry, metallurgy industry, etc. Ball mill can grind a wide range of materials, with enough continuous production capacity, simple maintenance. Capacity range from 5t/h to 210t/h. The feeding size is less than or equal to 30mm. Raw Mill; Cement Ball Mill; Coal Ball Mill

Cement Process & Energy Saving - eccj.or.jp

Cement Process & Energy Saving October, 2006 The Energy Conservation Center, Japan Taichiro Kawase. Laos 2006.10 2 Water Layout of one Japanese cement factory Waste tire yard Coal yard Electrostatic Precipitator Raw mill crusher SP & calciner Rotary kiln Cement silo Shipping pier Bird-eye View of Japanese Cement Factory. ... Elec Cons in Cement ...

in cement plant stone description of the raw …

role of raw mill in cement plant – Grinding . raw mill for cement plant - Coal Crusher ... stone description of raw mill supervisor in ... A raw mill is the equipment used to grind raw materials into "rawmix ... Get Price. Raw Milling Equipment Operator At Cement .

yanbu cement factory raw mill - People4Process

yanbu cement factory raw mill; International Projects Upcoming Projects in India New . Dangote Cement constructs a permanent coal-fired power.mill plant in Gladstone, Australia used to .Located on a 5.3 hectare plot of land in Raw.

Cement Plant Operations Handbook 5 - Advertisers Preview

Cement Plant Operations Handbook 5th Edition 17 SAMPLE 15. Cement Plant Assessment Data List 195 1. General – 2. Administration and Commercial – 3. Quarry – 4. Drying – 5. Raw Milling – 6. Blending – 7. Kiln – 8. Fuel – 9. Clinker – 10. Finish Mill – 11. Cement – 12. Quality Control – 13. Packing and Distribution – 14 ...